Introduction

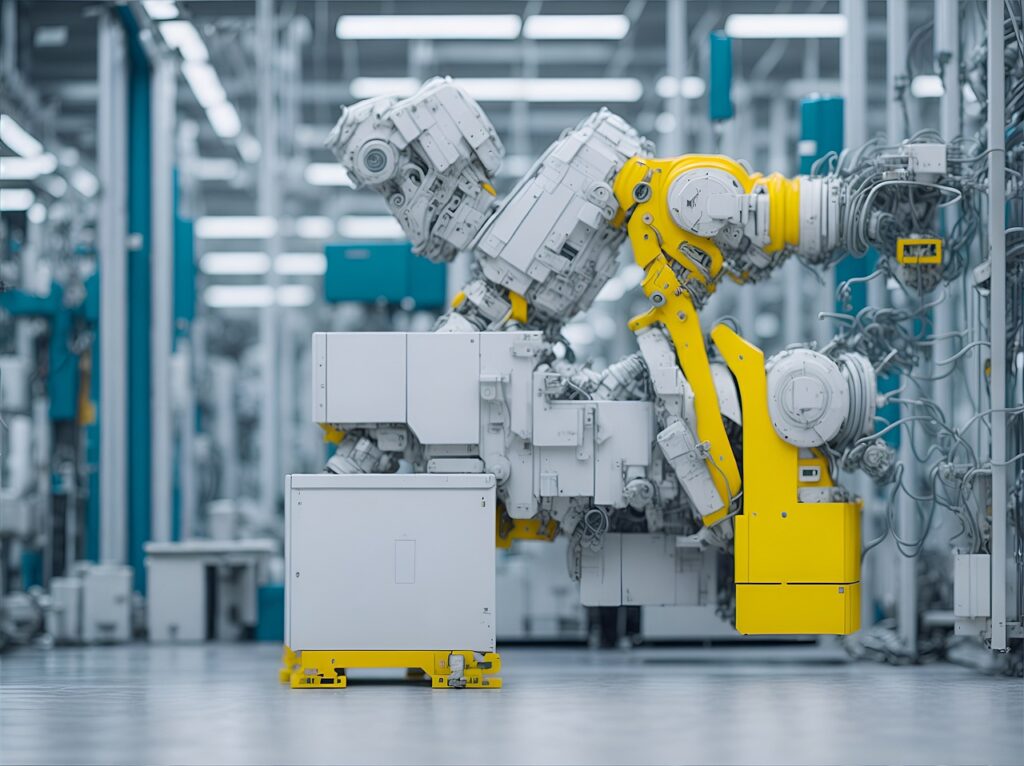

The manufacturing industry has undergone a remarkable transformation in recent years, fueled by technological advancements. Among these innovations, automation has emerged as a game-changer. As the need for improved productivity, efficiency, and cost-effectiveness continues to rise, automation plays a vital role in revolutionizing the manufacturing sector. In this blog, we will delve into the significance of automation in manufacturing and how it is reshaping the industry.

Enhanced Productivity

Automation serves as a cornerstone in boosting productivity across manufacturing processes. By replacing manual labor with automated systems, companies can achieve higher production rates, reduce errors, and optimize overall efficiency. Machines tirelessly perform repetitive tasks with precision, eliminating the risk of human error and ensuring consistent quality. Moreover, automation enables manufacturers to operate continuously, 24/7, minimizing downtime and maximizing output. Ultimately, increased productivity translates into greater profitability and provides a competitive edge for manufacturers in the global market.

Improved Efficiency and Quality

Automation brings forth an unprecedented level of efficiency that surpasses what can be achieved through manual labor alone. Automated systems can complete tasks at a faster pace and with greater accuracy, resulting in reduced cycle times and improved throughput. Additionally, machines are not subject to fatigue or distractions, allowing them to consistently maintain a high level of efficiency.

Automation also plays a significant role in quality control. By integrating sensors and monitoring systems, manufacturers can closely track and analyze every aspect of the production process. Real-time data enables swift identification and rectification of any deviations or defects, ensuring that products meet the required specifications. Consistent quality not only enhances customer satisfaction but also safeguards a manufacturer’s reputation and brand image.

Cost Savings and Return on Investment (ROI)

While the initial investment in automation may be substantial, the long-term benefits outweigh the costs. By automating tasks that were previously performed manually, manufacturers can significantly reduce labor costs. Machines work faster, more accurately, and for extended periods without requiring breaks or vacations. As a result, companies can reallocate human resources to more strategic roles that require creativity, problem-solving, and decision-making skills.

Automation also minimizes the risk of costly errors and rework. When processes are automated, the margin for human error decreases, ensuring that products are produced correctly the first time. This not only saves time but also reduces material waste and associated expenses.

Additionally, automation allows for predictive maintenance, where machines can monitor their own performance and identify potential issues before they lead to breakdowns. This proactive approach reduces unplanned downtime, improves maintenance efficiency, and extends the lifespan of equipment, further contributing to cost savings.

Workplace Safety

Safety is a crucial concern in any manufacturing environment. By automating hazardous or physically demanding tasks, manufacturers can significantly reduce the risk of accidents and injuries. Robots and machines can handle heavy lifting, operate in extreme temperatures, or work with toxic substances without endangering human workers. Employees can be assigned supervisory roles, overseeing automated processes and intervening only when necessary.

Furthermore, automation can improve ergonomic conditions by eliminating repetitive motions or awkward postures that can lead to musculoskeletal disorders. By creating a safer work environment, manufacturers enhance employee well-being, reduce the number of workplace incidents, and ultimately boost morale and job satisfaction.

Conclusion

Automation has become an indispensable component of modern manufacturing. Its ability to enhance productivity, improve efficiency and quality, generate cost savings, and ensure workplace safety makes it a critical driver of progress in the industry. Manufacturers who embrace automation gain a competitive advantage, enabling them to meet increasing customer demands, reduce time-to-market, and maintain profitability in a rapidly evolving global market. As automation continues to evolve and intertwine with emerging technologies like artificial intelligence and the Internet of Things, its significance in manufacturing will only continue to grow, unlocking new possibilities and transforming the way we produce goods.